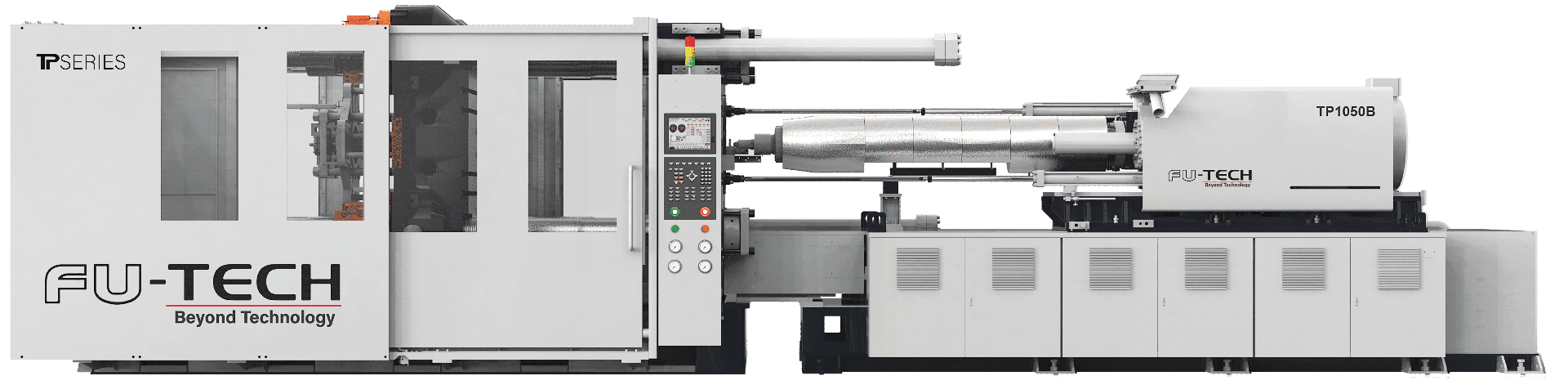

TP SERIES

Injection Moulding Machines

The TP Series is the perfect solution for large injection molding machines. This is a Two-Platen mechanism and is different from regular three platen toggle mechanism. The general machines in large tonnages occupies lots of space and offers very less opening stroke. The TP Series is the solution for this problem as it offer a huge Opening stroke and Daylight with lowest Footprint. The TP Series is Faster in comparision with other Standard machines. The TP Series is the ideal selection for manufacturing large Automotive, Household components. The TP series offers wise range of tonnages from 650 Ton to 4000 Ton.

Clamping Unit

- Larger space between tie-bars, suitable for larger and multi-cavity molds.

- Rigid Locking Nut Design making Nut Clamp operation fast and smooth without jerks.

- Longer and wider guide length, higher precision, improved product quality and mold working life.

- Graphite-Copper bushes in Tie-Bar, slider movable platen ensures fast and precise mold close and open.

- High speed Moving platen movement with dynamic control of braking and start

- Close loop safety for Human detection inside the machine clamp area

- Automatic Servo controlled front Sliding Gate for better safety, Convinieance and cycle time.

- Rigid platen and mechanical systems ensures longer machine life.

- Closed Loop progressive type lubrication system controlled by PLC

- Clamp Nut and Locking cylinders on Moving plate making it easy to maintain

- Automatic Die-Height adjustment feature for precise and easy mold setup

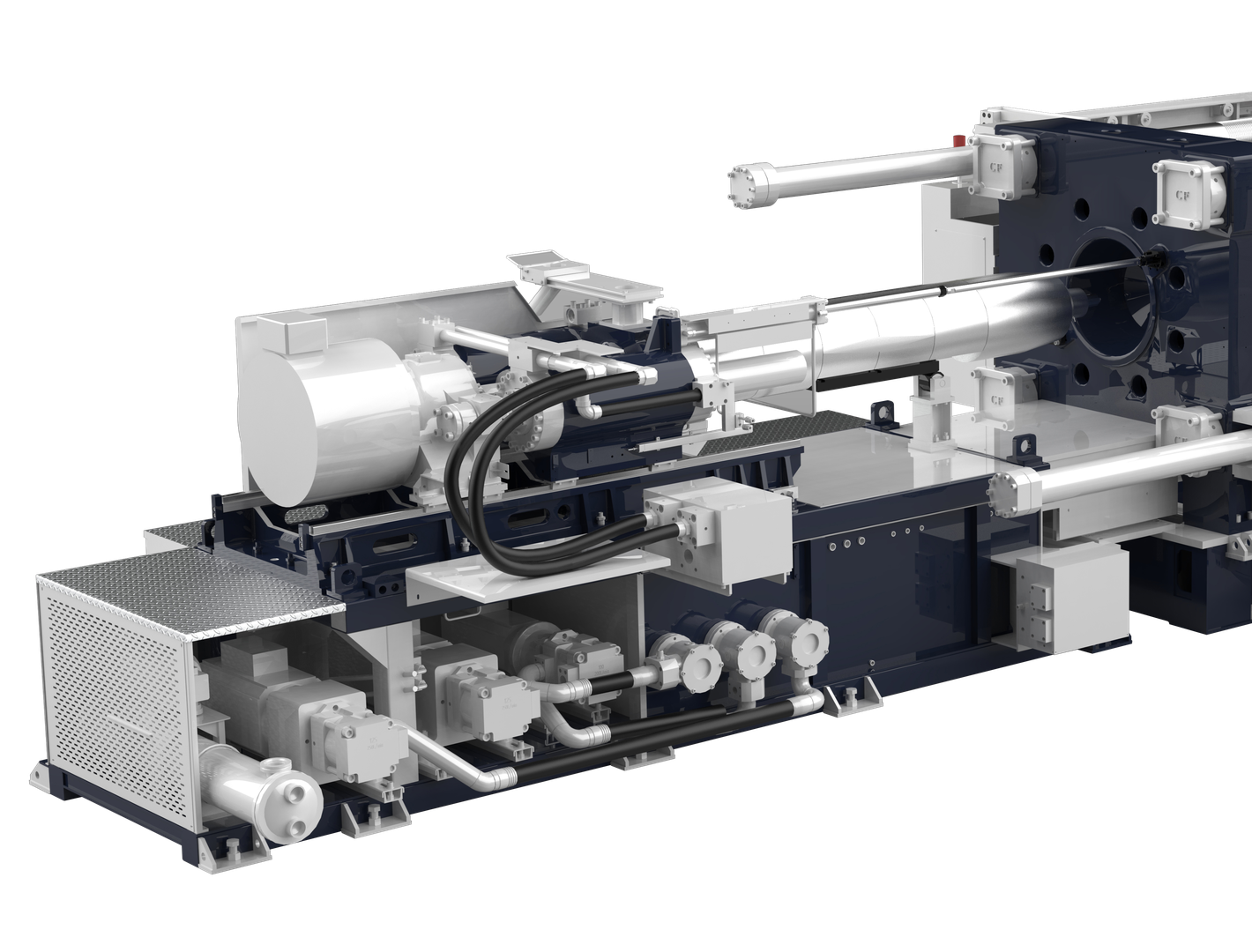

Injection Unit

- Injection unit with dual precise linear guide rails, ensuring the precision and fast speed

- Dual carriage cylinders improve a better injection precision

- No welding, Adaptor design ensures easier maintenace and repairs

- Upturning designed nozzle cover make production and maintenance easier

- Longer Injection Strokes for larger Shotweight for large components.

- High Injection speeds of upto 100mm/sec for saving good amount of Cycle time.

- Imported high quality SKD61 material ring, cone and plunger; lots of screw design can meet different plastic materials and special processing injection molding needs