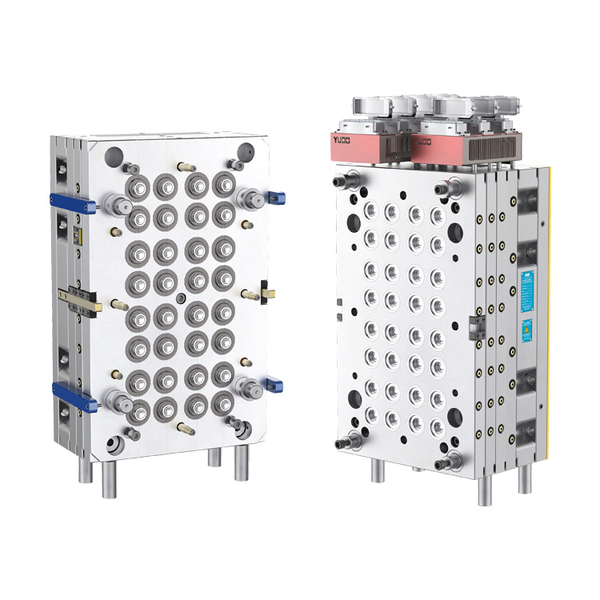

PLASTIC INJECTION MOULDS

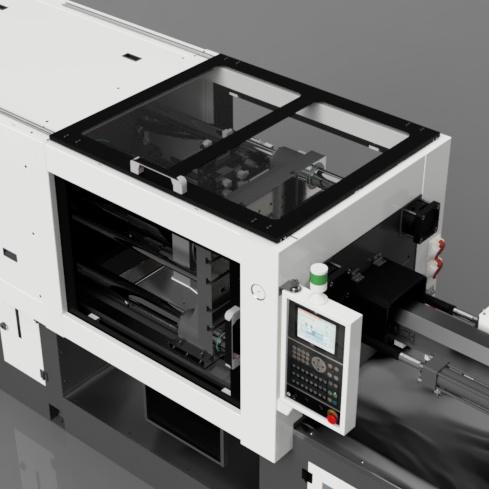

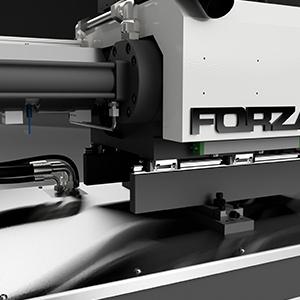

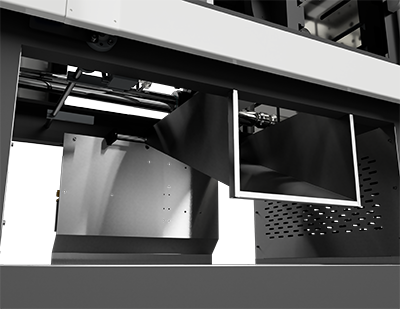

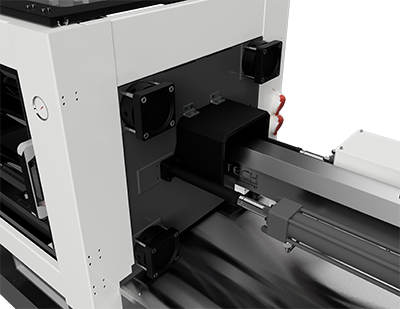

At Futech Machinery, we design and manufacture high-performance plastic injection moulds that deliver durability, efficiency, and superior finish. With decades of expertise in injection moulding technology, we ensure that every mould is crafted with precision to meet global standards while being 100% Made in India. Our moulds are compatible with a wide range of injection moulding machines, including our own Futech Injection Moulding Machines, ensuring maximum efficiency and long tool life.

Why Choose Futech Moulds?

High Precision & Accuracy → Engineered with advanced CAD/CAM and CNC machining.

Our moulds are engineered using advanced CAD/CAM design and CNC machining, ensuring consistent dimensions and accuracy for every part produced.

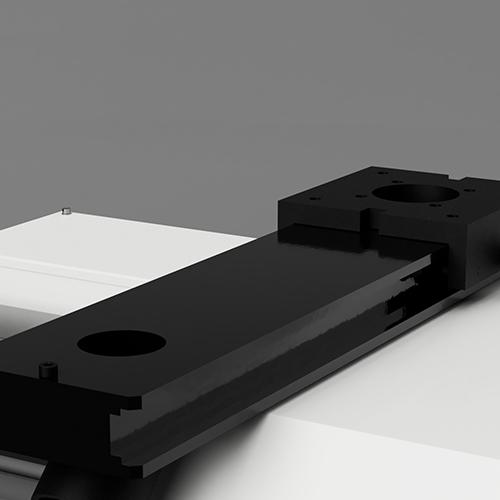

Long Tool Life

We use premium-grade tool steel, proper heat treatment, and advanced surface finishing techniques, which give our moulds exceptional durability and reduced maintenance.

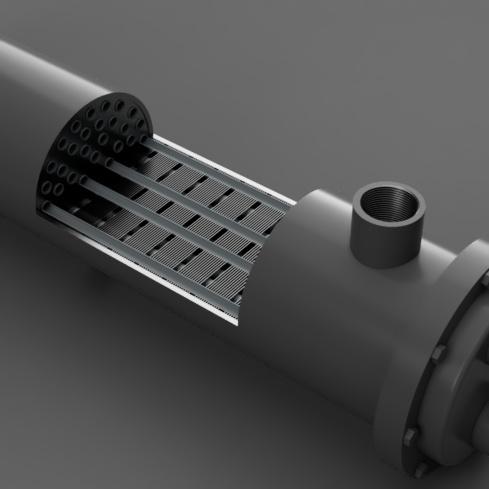

Faster Production Cycles

Optimized cooling channels and runner systems allow shorter cycle times, helping manufacturers increase production efficiency and lower costs.

Customization for Every Requirement

Every industry and product is unique. That’s why we provide custom mould design services to meet your exact production needs—whether it’s a single-cavity mould or a complex multi-cavity hot runner mould.

Thin Wall Container Moulds

High-performance Thinwall Container Moulds designed for fast cycle times, precision, and durability. Our moulds are engineered to produce lightweight containers with uniform wall thickness, superior clarity, and maximum strength. Futech is a prooven Packaging moulds supplier in India now.

PET Preform Moulds

High-quality PET Preform Moulds with precision engineering for consistent preform weight, clarity, and strength. Designed for high productivity, long mould life, and easy maintenance.

Automotive Moulds

Futech being best Automotive moulds manufacturer only deals in precision-engineered Automotive Moulds for dashboards, bumpers, interior & exterior parts. Built for durability, accuracy, and high-volume production in the automotive industry.

Home Appliance Moulds

High-precision Home Appliance Moulds for washing machines, refrigerators, air conditioners, and kitchen appliances. Durable, accurate, and optimized for high-volume production.

Medical Moulds

High-precision Medical Moulds for syringes, IV sets, diagnostic components, and other healthcare products. Designed for accuracy, hygiene, and reliable high-volume production.

Engineering Component Moulds

Industrial plastic moulds,Multi-cavity,Hot runner moulds India, injection moulds engineering Component Moulds for industrial parts with high strength, precision, and durability. Designed for complex geometries, tight tolerances, and long production life.

Frequently Asked Questions (FAQs) About Futech Moulds

1. What materials are used in Futech injection moulds?

We use high-quality tool steels such as P20, H13, and stainless steel depending on the application. All materials undergo proper heat treatment to ensure long tool life, durability, and resistance to wear.

2. Can Futech moulds be customized for specific products?

Yes.As Futech is Best plastic mould manufacturers in India, We specialize in custom mould design and manufacturing. Whether you need automotive parts, household items, or packaging solutions, our team can design moulds tailored to your exact product specifications.

3. Do you provide trial and testing before delivering moulds?

Absolutely. Every mould undergoes trial runs and testing at our facility to ensure accuracy, surface finish, and cycle time optimization before dispatch. This guarantees smooth operation at your production line.

4. What industries commonly use Futech moulds?

Our moulds are widely used in automotive, packaging, electronics, medical, and consumer goods industries. From dashboards and crates to caps and household products, we provide moulds for a wide range of applications.

5. How long does it take to manufacture a mould?

The production time depends on the complexity and size of the mould. A simple single-cavity mould may take 4–6 weeks, while complex multi-cavity or hot runner moulds may take 8–12 weeks.