FORZA SERIES

Injection Moulding Machines

The FORZA Series is our latest high performance offering ranging from 60 Ton to 410 Ton. Equiped with high speed servo system, these machines are ideal for high production output.

Clamping Unit

- Direct Locking

- Smaller Foot Print

- Larger Tie-Bar Distance

- T-slot Platen

- Quick Mold Change

- Perfect Parallelism

- Low Maintenance Cost

- Easy Clean Heat Exchanger

Injection Unit

- High Speed Plastisizing

- Multiple Choices for Injection Unit

- High Precision Linear Guide

- Bigger Shot Size

- Hybrid Servo System

- Low Energy Consumption

- High Accuracy Control

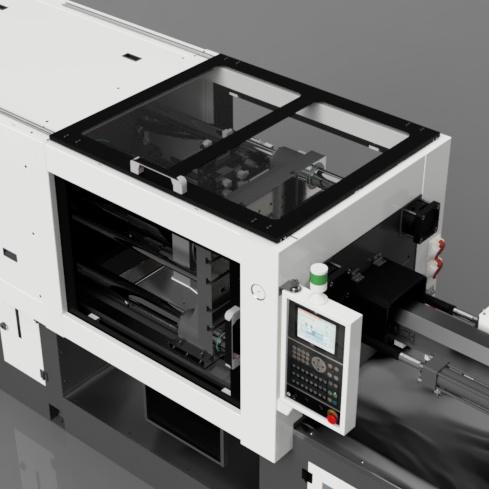

Sliding Top Cover

The sliding cover offers dust protection along with increasing the overall machine safety. The dust protection inturn increases the hydraulic oil & seal life.

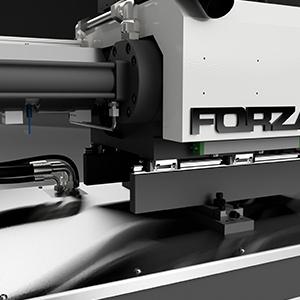

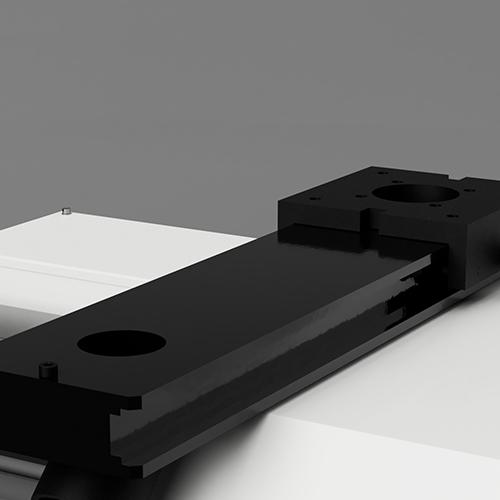

Injection Unit with Linear Guide Rails

The friction-less linear guide rails provides precise, high speed and accurate injection. Also stainless steel covers below injection unit increase over all machine cleanliness.

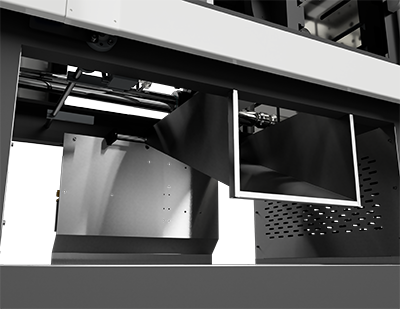

Adjustable Tray & Stainless Steel Covers

The adjustable taper tray suits all your mould needs and the staineless steel covers provide extra hygiene and cleanliness which is suitable for food grade and medical applications.

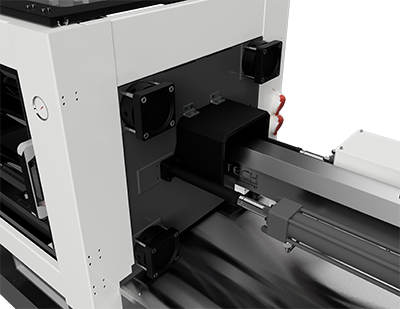

Purge Safety Guard

The safety guard provides extra safety during barrel purging and cleaning. The upturning design makes switching between maintainence and production easier.

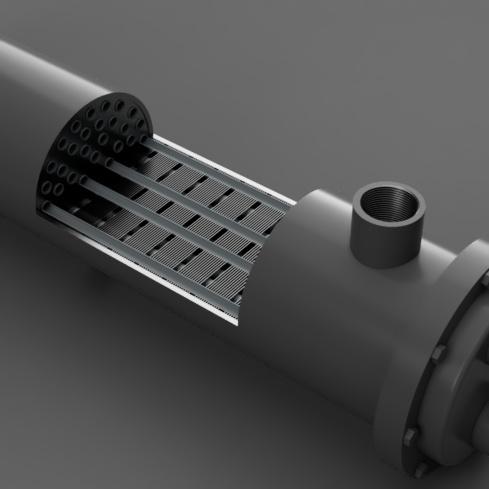

Heat Exchanger with Fins

Specially designed heat exchanger with high heat transfer rate provides adequate cooling for your machine and keeps it cool during 50 degree summers and increases machine and hydraulic oil life.

Easy Slide Hopper

The bearing design makes moving the hopper effortless. Even fully loaded hopper-dryer can be moved, shifted, adjusted just with push of a finger.