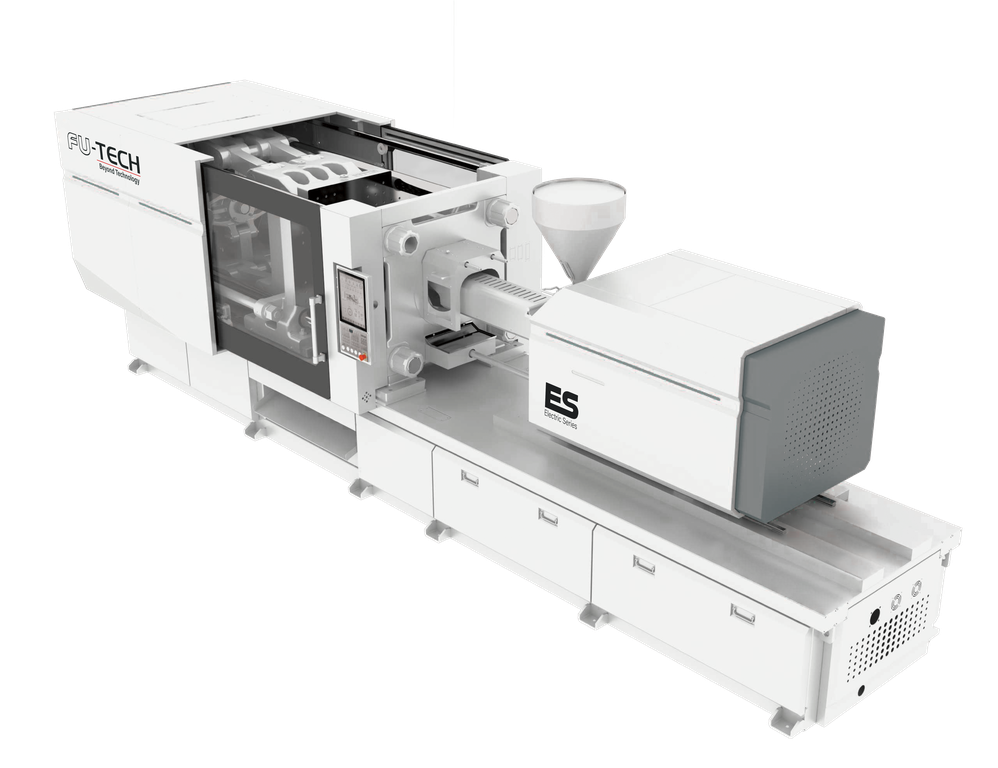

ES Series All Electric

Injection Moulding Machines

The ES Series is our latest high performance All ELectric Injection Moulding Machine; ranging from 120 Ton to 450 Ton.The ES Series fast, accurate and smooth axis movements. The ES Series is equipped with High speed servo motors on all axis paired with Japanese ball screw ensuring accurate functions. The ES Series offers lowest dry cycle time with lowest electricity consumption.ES Series is suiteable for accurate engineering moulding, Thin wall containers and in-mould labeling and other high speed injection moulding applications.

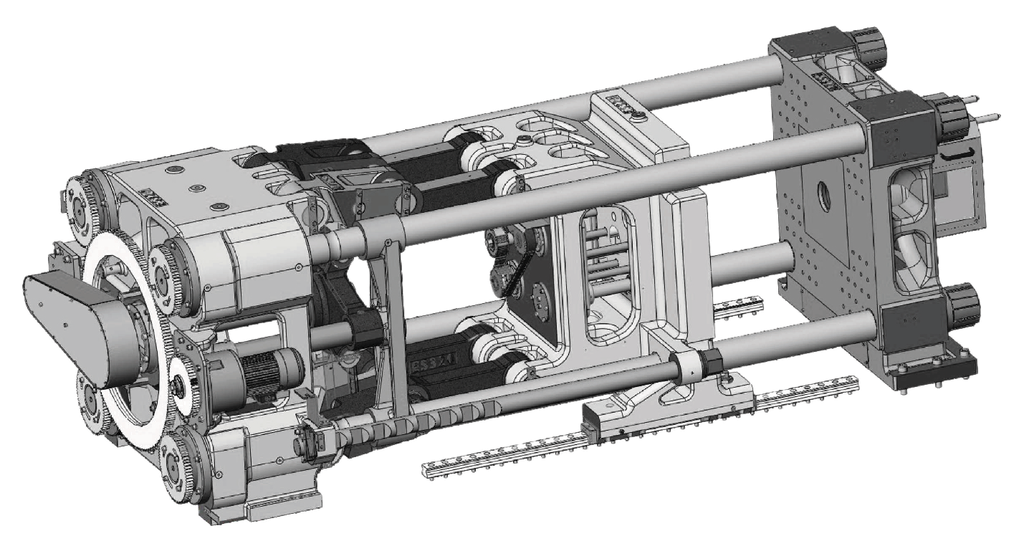

Clamping Unit

- Independent crosshead support structure improving accuracy of crosshead guide rod enhancing ball screw life

- Clamping unit on Linear guide and Bushless Tie bar contact ensuring oil-free area for component

- Mould closing and opening speed more than 800mm/sec with accuracy and smoothness

- Die Height adjustment more faster and accurate control using Electric motor

- Toggle clamp structure is very rigid and suiteable for applications cycle time less than 6 Seconds

- Self Lubricated bushing from Japanese manufacturer offers longer toggle bush life.

- High speed platen axis movement without jerks and spikes.

- Closed loop grease lubrication system for toggle bushings.

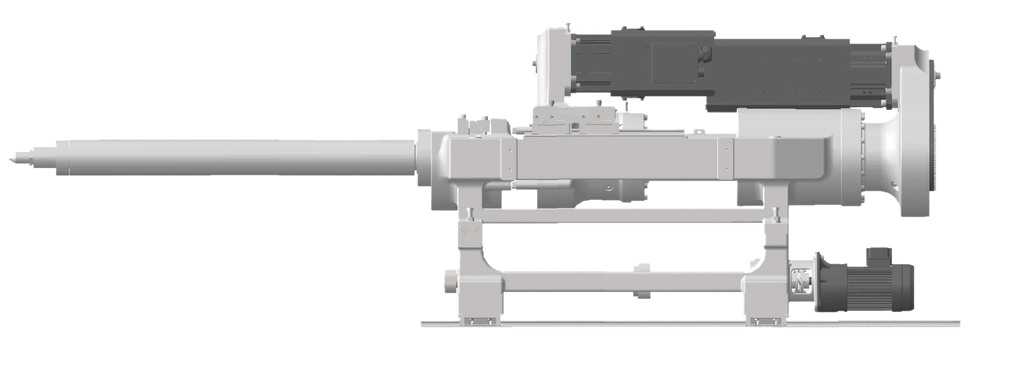

Injection Unit

- High injection speeds upto 350mm/sec with accuracy and smoothness

- High screw RPM offers low refilling time means low cycle time

- Enhanced efficient Screw Design saves Charging time and Electricity

- High Precision Linear Guide rails and japanese ball screw for less frictional drag

- Larger screw size and stroke with longer L/D Ratio for High production output

- Enhanced dynamic control for back pressure using servo motor

- Nozzle contact force accurately driven by electric motor and ball screw

- Enhanced accuracy of injection and charging axis function